ARTICLE FROM SPORTS TEXTILES PUBLISHED 24/07/2024

NO WOOD TO WASTE

In addition to going into manmade cellulosic fibres, the renewable resource that is pulped wood is also being tapped for other textile industry supplies, including polymers and chemicals, offering a new array of materials that are not derived from fossil fuels.

For makers of wood-based fibres, nothing is lost. The parts of timber that are not turned into cellulose pulp are commonly used to power the factories that make viscose-family fibres. Now, as the race heats up to find alternatives to petrochemicals, some trailblazing companies are finding other ways to transform this natural and renewable raw material into polymers and chemicals.

Many seek to use only leftover wood. The timber industry, like that of apparel, generates its fair share of waste. “In the US alone, it is 50 million tonnes every year,” says Jane Palmer, founder and CEO of Nature Coatings. For Kristoffer Ekman, co-founder of NordShield, waste is not the proper term: “I wouldn’t talk of waste, as everything is used in forestry.” He sees it as a ‘residue’ that is full of resources, and he is not alone.

FROM CHEMICALS AND PIGMENTS

The result of more than a decade of research, the antimicrobial finish that NordShield has developed and patented is drawn from pine tree resin, “a side stream of the forestry industry,” Mr Ekman tells WSA. “Since the early 1980s, the inventor of the process had been looking for a sustainable alternative to biocides. He tested a wide array of substances and found that pine tree resin was a highly effective antimicrobial agent, which has been used in wound-care for ages.” Based in Espoo, Finland, and founded in 2016, the company launched its biobased odour-capturing technology, NordShield Crisp, last year. “It is a non-biocidal, non-leaching, biodegradable and plant-based anti-odour technology,” he says. The finish is said to form a two molecule-thick film on the surface of the textile, and can withstand up to 30 washes. “It is a physical film, but it doesn’t impact hand-feel,” he adds.

In addition to NordShield Crisp, made for cellulose-rich fabrics, the company also offers a citric acid-based antimicrobial for synthetics, NordShield Citex, which is also biobased and biodegradable. “Safe by design is an important principle for us,” says Mr Ekman.

"Consumer awareness is growing, and many mills and brands are switching away from metal-based biocides.” The wood resin-derived finish is in advanced trials at major brands, is already being used by a shoe manufacturer in Asia, and he expects to be able to announce specific collaborations with brands and mills later this year.

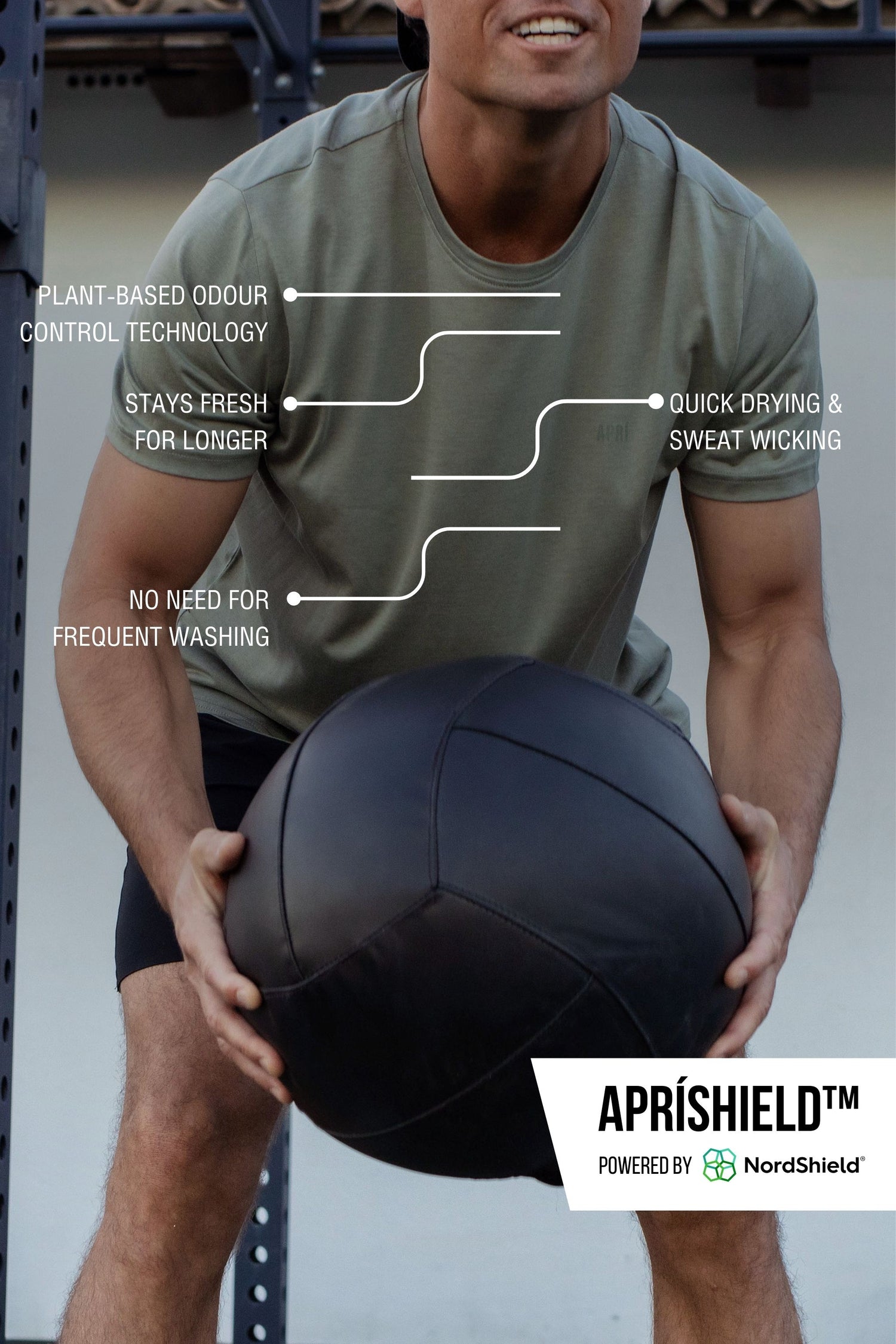

Start-up Scandinavian athleisure brand APRí Sportswear launched its first series of products this June, incorporating NordShield Crisp-treated loungewear in a cotton-lyocell blend. Brand co-founder Evelina Boström seeks to make high-quality activewear designed for longevity, which brought her to choose the plant-based anti-odour finish. “It allows users to wash their clothes less often and thus saves energy and water. It reduces their carbon footprint and preserves the garment itself,” says Ms Boström, who describes NordShield’s Crisp as “ground-breaking”.

-----

ANTI-ODOUR TREATMENT FROM NORDSHIELD

“Our mission at Nordshield has from the very beginning been to harness the power of nature to improve everyday life. By collaborating with the APRÍ team, we can bring our state-of-the-art anti-odour technology to a broader audience, enhancing the longevity of their already exceptional high-quality apparel. APRÍ shares the same values and attitude that our company wants to be associated with, making this partnership a perfect fit,” commented Nordshield co-founder Kristoffer Ekman.